Sustainable lab equipment that costs less

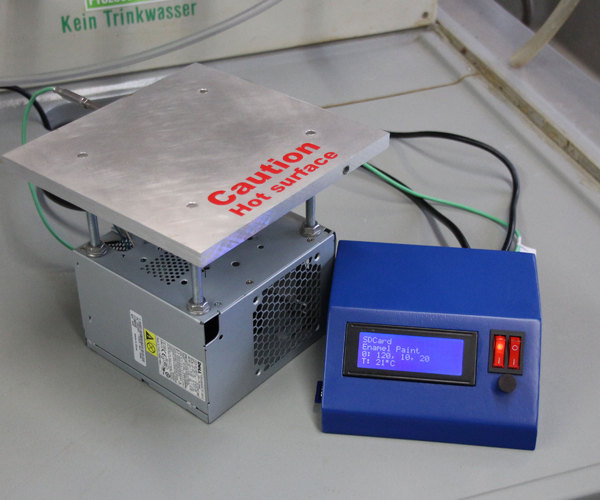

Researchers looking for ways to save costs in running their laboratories should consider 3D printing. This post idea came to me through the article 3D Printing Provides Cost Effective Alternative to Expensive Lab Equipment Plus R&D Tax Credit. Looking further I found this Open-source Scientific Tools collection on Thingiverse with a gel electrophoresis system, test tubes, a magnetic stirrer, micro pipettes, microscopes and even a Geiger counter! I quickly found other resources like the NIH 3D Print Exchange for custom labware, Open-Labware.net and Instrucables.com. It turns out that there are hundreds of open source lab equipment and supply 3D printer design files online. Improvements in 3D printer technology has made 3D printers cheaper to buy and easier to use - making them more accessible to scientists.

Here are a few publications that exemplify how 3D printing can significantly reduce laboratory costs. New equipment can be produced and the life of used lab equipment is extended by repair or adding functionality. You'll appreciate some of the impressive customization!

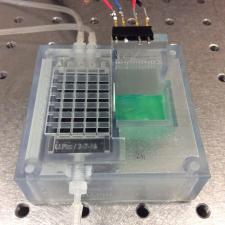

DNA Assembly in 3D Printed Fluidics PLoS ONE

3D-printing your lab equipment—it’s cheaper than you think by Joshua M. Pearce PhD Michigan Technology University

Click images and hover above for credit and source links.

3D printing scientific lab equipment can be eco-friendly

My next question was how can 3D printed lab supplies be more sustainable than ordering from a catalog? Most plastic lab supplies are produced by injection molding. This new paper Environmental and Economic Implications of Distributed Additive Manufacturing: The Case of Injection Mold Tooling (2017) Jrnl. Industrial Ecology reports how the alternative process of 3D printing yields a reduction potential of 3% to 5% in primary energy, 4% to 7% in GHG emissions, 12% to 60% in lead time, and 15% to 35% in cost over injection molding. 3D printer companies themselves help support sustainability efforts by accepting used cartridges, canisters, spools, print engines and containers for return, or recycle. All this green potential can go even further with some consideration to the plastic filament you use to print.

Eco-friendly filament for 3D printing

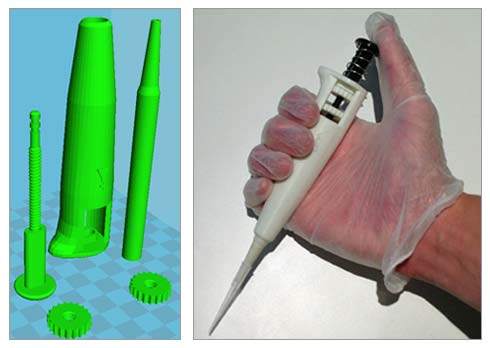

There was once no such thing as completely eco-friendly 3D printing with plastic. The common filaments that feed plastic into 3D printers are composed of either acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA). PLA has always had the sustainable attribute of being a plant based bio-plastic. According to the article, Is Recycling PLA really better than composting? the environmental impact of recycling PLA is over 50 times better than composting, and 16 times better than incinerating PLA. Unfortunately PLA is not a sturdy enough material for most lab supplies. ABS on the other hand is a wonderfully sturdy material, but is not eco-friendly. To picture ABS picture a micro pipette or lego bricks. These items generally don't get processed by local recycling companies. There are recycling machines sold for use with 3D printers that can turn ABS or PLA objects back into filaments. Unfortunately, it can be tricky to ensure that the new filament is sufficiently pure for reuse in a 3D printer. These have been the challenges to eco-friendly 3D printing.

Fortunately there is a relatively new filament called "Enviro ABS" made by the company 3D Printlife. While regular ABS filament may require around 1000 years to disintegrate in a landfill, this filament will be gone in around 12 years. As per the company's comments on their ASTM D5511 testing, which is the “Standard Method for Determining Anaerobic Biode-gradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions”. This predicted degradation time is dependent on the shape of the object. Certainly there would be a big difference between a small test tube and thicker parts to a microcentrifuge. The manufacturer uses an additive that allows it to be broken down by bacteria in a landfill to energy facility or a commercial compost. Eco-friendly 3D printing...Voila!

PLoS One Fig 1. DNA assembly in 3D-Printed Fluidics.